What is an Oil and Grease Separator?

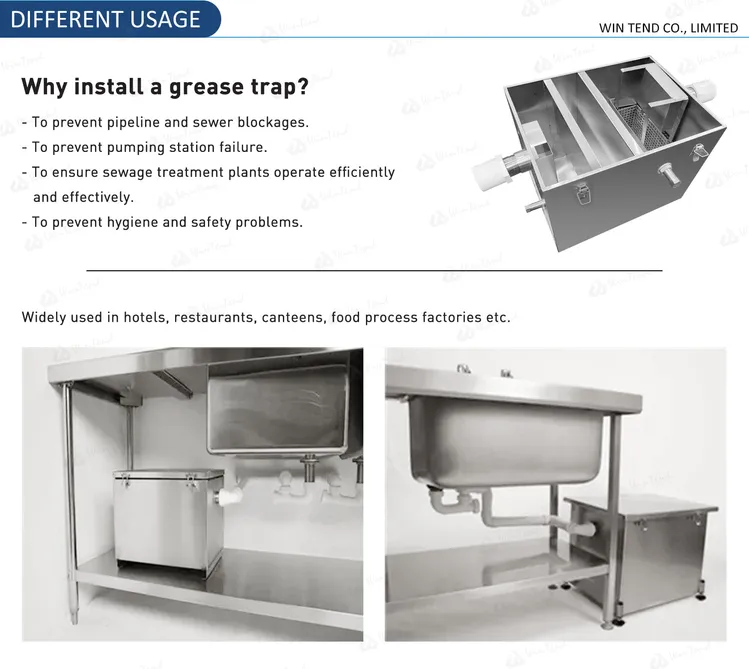

An oil and grease separator is a specialized device designed to remove oil, grease, and other hydrocarbons from wastewater before it enters the sewage system or natural water bodies. These separators are essential in industries and facilities where oily wastewater is generated, such as restaurants, automotive workshops, manufacturing plants, and food processing units.

Why Are Oil and Grease Separators Important?

Oil and grease can cause significant environmental and operational problems if not properly managed. They can clog sewer lines, interfere with wastewater treatment processes, and pollute water bodies, harming aquatic life and ecosystems. Installing an oil and grease separator helps prevent these issues by capturing and removing contaminants at the source.

How Does an Oil and Grease Separator Work?

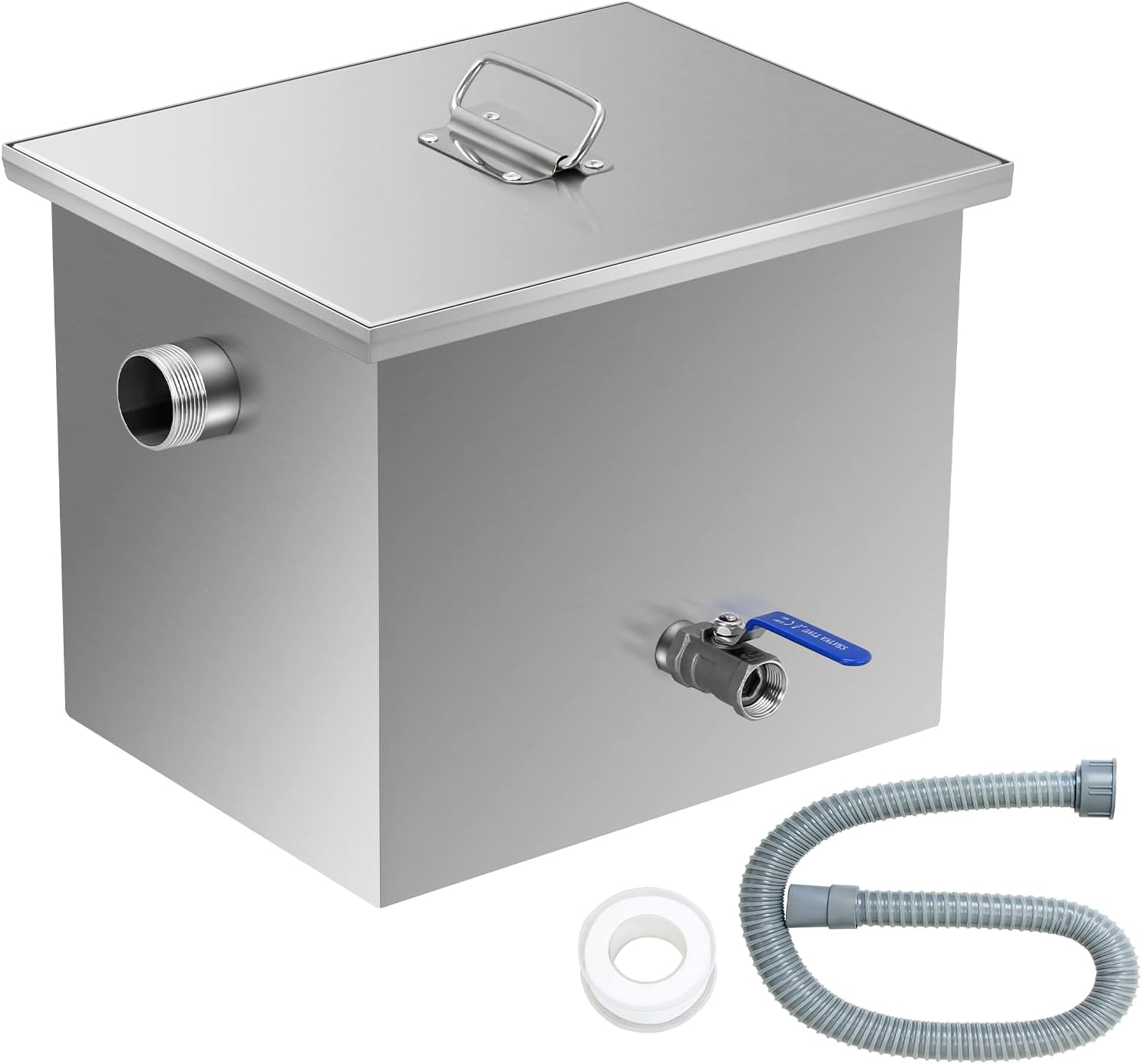

Oil and grease separators operate based on the principle that oil and grease are lighter than water and will naturally float to the surface. The separator allows wastewater to flow into a tank where it slows down, enabling the oil and grease to separate and rise to the top. The cleaner water then exits the tank, while the accumulated oil and grease are periodically removed.

Typical Components:

| Component | Function |

|---|---|

| Inlet | Entry point for wastewater |

| Separation Chamber | Allows oil and grease to separate from water |

| Outlet | Discharges treated water |

| Oil Skimmer | Removes floating oil and grease |

| Sludge Trap | Collects heavier solids that settle at bottom |

Types of Oil and Grease Separators

- Gravity Separators: Use gravity to separate oil and grease from water.

- Coalescing Separators: Use coalescing media to enhance separation efficiency.

- Centrifugal Separators: Use centrifugal force to separate contaminants.

Maintenance and Best Practices

Regular maintenance is crucial for optimal performance:

- Inspect and clean the separator regularly.

- Remove accumulated oil, grease, and sludge.

- Monitor flow rates to prevent overloading.

- Follow manufacturer guidelines for servicing.

Benefits of Using Oil and Grease Separators

- Protects municipal sewer systems from blockages.

- Reduces environmental pollution.

- Complies with local regulations and standards.

- Enhances the efficiency of wastewater treatment plants.

Frequently Asked Questions (FAQ)

Q1: Where are oil and grease separators commonly used?

A1: They are widely used in commercial kitchens, automotive service centers, industrial plants, and any facility generating oily wastewater.

Q2: How often should an oil and grease separator be cleaned?

A2: Cleaning frequency depends on usage but typically ranges from monthly to quarterly.

Q3: Can oil and grease separators handle all types of oils?

A3: Most separators are designed for common oils and greases but may require specific designs for heavy or emulsified oils.

Q4: Are oil and grease separators mandatory?

A4: Many local regulations require their installation to protect sewer infrastructure and the environment.

By understanding what an oil and grease separator is and how it functions, businesses can better manage their wastewater, comply with regulations, and contribute to environmental protection.