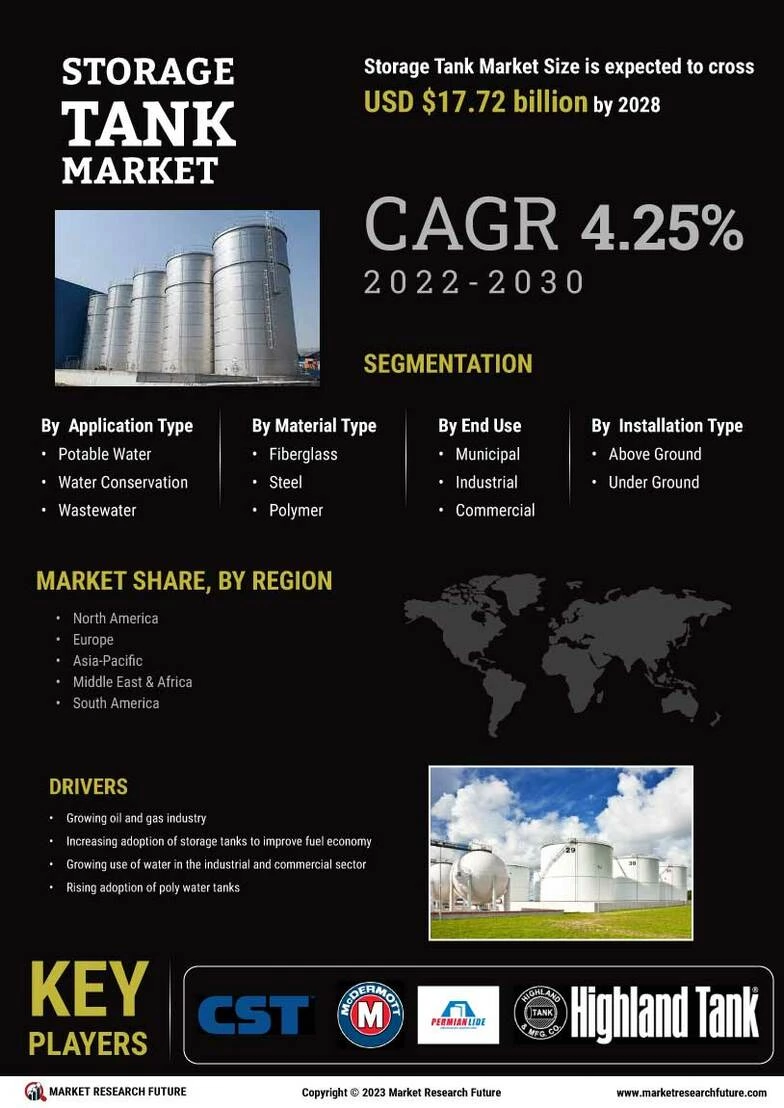

Market Trends: Fiberglass vs. Plastic Tank Demand

Understanding the evolving market trends between fiberglass and plastic tanks is crucial for manufacturers, suppliers, and consumers alike. This article explores the demand dynamics, advantages, disadvantages, and future outlook of both materials.

Introduction

Tanks made from fiberglass and plastic are widely used across various industries, including water storage, chemical processing, and agriculture. Each material offers unique benefits and challenges that influence market demand.

Market Demand Overview

| Material | Current Demand Level | Growth Rate (Annual) | Key Industries |

|---|---|---|---|

| Fiberglass | Moderate | 5% | Chemical, Industrial, Marine |

| Plastic | High | 8% | Agriculture, Residential, Retail |

- Fiberglass tanks are favored for their strength and resistance to corrosion, making them ideal for harsh environments.

- Plastic tanks are popular due to their cost-effectiveness, lightweight nature, and versatility.

Advantages and Disadvantages

Fiberglass Tanks

- Advantages:

- High durability and strength

- Excellent chemical resistance

- Long lifespan

- Disadvantages:

- Higher initial cost

- Heavier and more difficult to transport

- Susceptible to UV degradation without protective coatings

Plastic Tanks

- Advantages:

- Lower cost and lightweight

- Easy to install and transport

- Resistant to many chemicals

- Disadvantages:

- Less durable under extreme conditions

- Can degrade under prolonged UV exposure

- Limited load-bearing capacity

Factors Influencing Demand

- Environmental regulations: Stricter rules on chemical storage impact material choice.

- Technological advancements: Innovations in plastic composites and fiberglass manufacturing affect market preferences.

- Economic conditions: Cost sensitivity drives demand for plastic tanks in budget-conscious markets.

- Industry-specific needs: Certain industries require specific material properties, influencing demand.

Future Outlook

The demand for plastic tanks is expected to grow faster due to their affordability and adaptability, especially in emerging markets. However, fiberglass tanks will maintain steady demand in sectors requiring high durability and chemical resistance.

FAQ

Q1: Which tank material is more environmentally friendly?

A1: Both materials have environmental impacts, but plastic tanks can be recycled more easily, while fiberglass production is more energy-intensive.

Q2: Can fiberglass tanks be repaired if damaged?

A2: Yes, fiberglass tanks can often be repaired using resin patches, extending their service life.

Q3: Are plastic tanks suitable for storing all types of chemicals?

A3: Plastic tanks are resistant to many chemicals but may not be suitable for highly aggressive substances; material compatibility should be verified.

This comprehensive overview provides valuable insights into the current and future market trends of fiberglass versus plastic tanks, helping stakeholders make informed decisions.